Why simulate the injection moulding process?

Questions every mould designer asks ?

-

Will the mould fill?

-

Where are the air traps and weld lines?

-

Will the mould fill the first time?

-

Where might a sink mark occur?

-

Is my gate in the right place and size?

-

Is this mould balanced?

-

What cycle time can we expect ?

IMPACT OF CHANGE

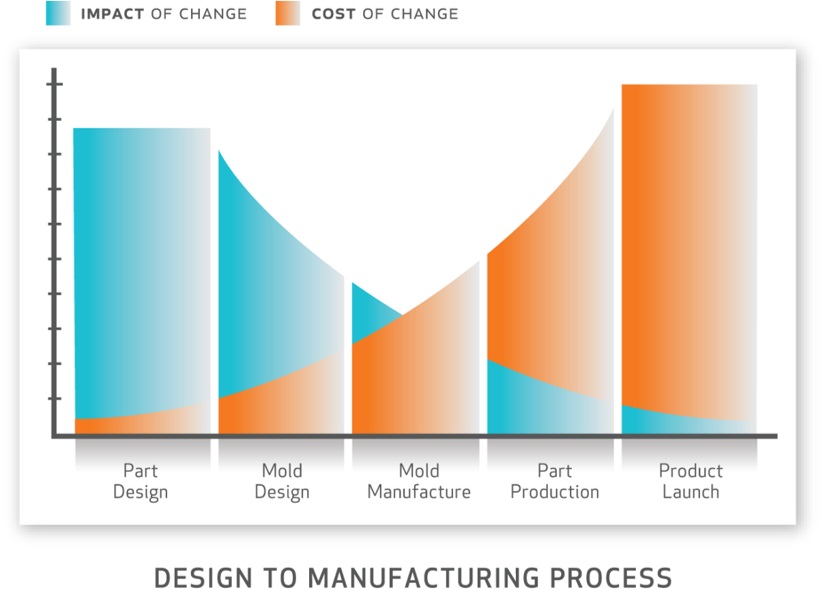

Why should you be concerned about using SOLIDWORKS Plastics during the earliest stages of design? Because that’s when the cost of change is least and the impact of that change is the highest. In other words, when you make changes during part design, it’s to a 3D CAD model, but if you have to make those changes during part production, you might be re-welding and cutting steel – a very costly and time-consuming process. And because of the inherited constraints, the changes you make at that point may have little to no effect on the manufacturability of the part.

"SOLIDWORKS Plastics has given us the ability to produce moulds faster and more accurately . Currently we have 100% success rate." Bastian Strauf - Power Logic

Join our webinar !

Join our webinar and learn how to set up a study in SOLIDWORKS Plastics to predict and avoid defects, eliminate mold rework, increase part quality, cut time to market, and create designs that are optimal for injection molding. Which will include and interview with a SOUTH AFRICAN company describing how they benefited from using SOLIDWORKS PLASTICS.